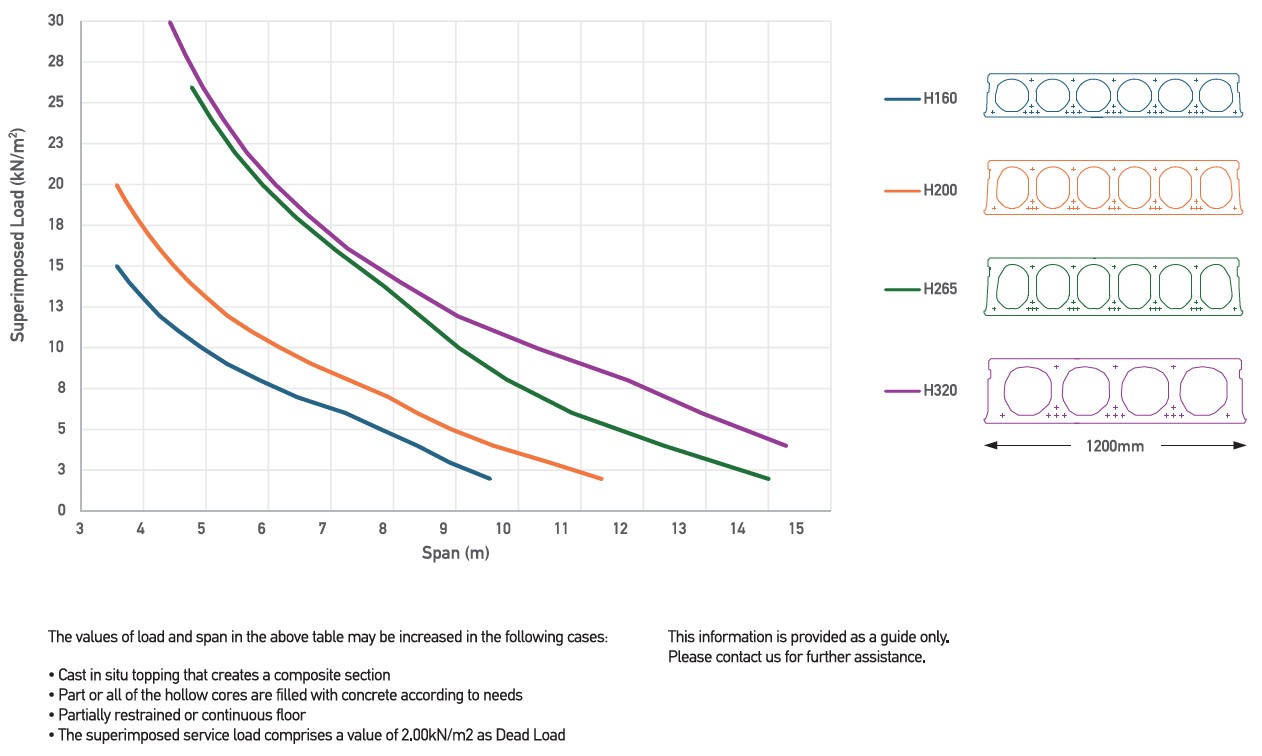

The Hollow Core slab is a Precast Prestressed Concrete Slab with tubular voids which run through the full length of the slab, thereby reducing the weight of the unit. With the benefit of prestressing and low self weight, longer spans can be achieved for the same loads or greater loads for the same slab height.

Get the detailed data sheets and design guides below

ARMOS has a fully automated production line exclusively for Hollow Core Boards, ensuring consistent quality, precision and efficiency at every stage.

With a production capacity of 500 m² per shift — and up to 1,000 m² per day — our advanced equipment achieves high efficiency, fully complying with European standards.

Watch the video below to see our production process in real time.

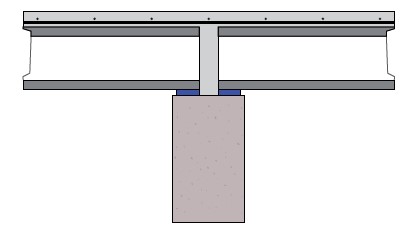

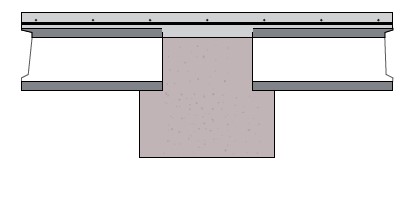

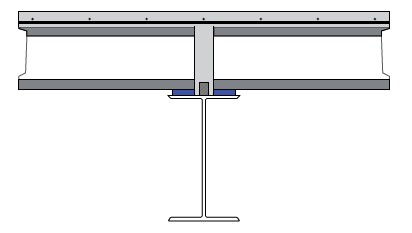

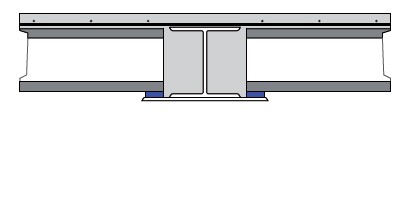

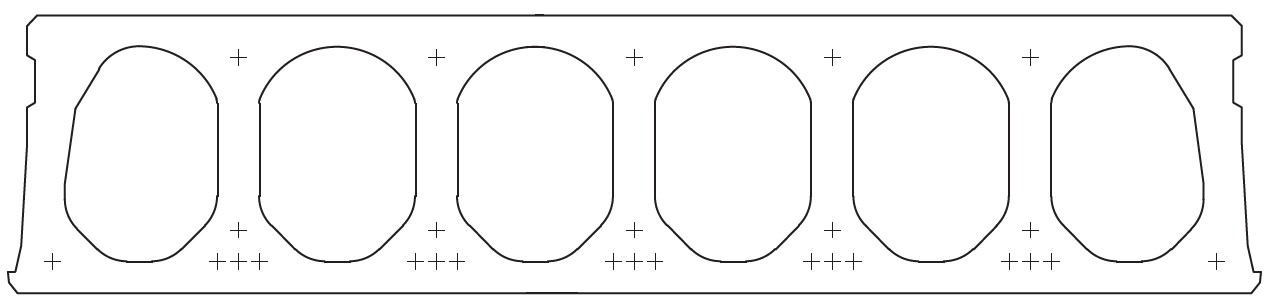

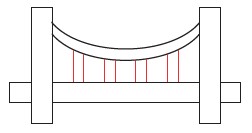

These diagrams are for guidance purposes only.

Specific reinforcement and prestressing details have been omitted for clarity.

Please contact us for further assistance.